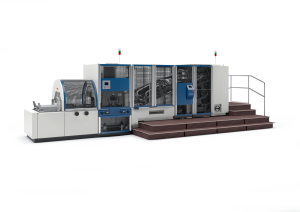

Wasatch Container Expands, Adds Kolbus RD 115S Flexo RDC

“We’re excited to upgrade our rotary die cut print capabilities and offer our customers new options from the Kolbus RD115S,” said Frisch. “The ability to print on two sides in a single pass will boost throughput in the plant and increases Wasatch Container’s value to our customers. The German built RD 115S fully servo flexo rotary die cutter is the newest advancement from Kolbus. This machine features advanced technology including image stretch/shrink functionality, plate skewing for fine adjustments without opening the machine, a feed unit with repeatable sheet separation with servo driven feed wheels and lift grid, and a rigid cast iron frame die cutter module.

Wasatch Container will be the first in their region with this new Kolbus RD 115S technology, and the second in North America to purchase this innovative machine. “We look forward to partnering with Wasatch Container on increasing their print capabilities and continuing to grow their already successful corrugated business,” said Jeff Dietz, Kolbus America President. “The RD 115S is a premium, German-engineered rotary die cutter with stateof- the-art automation, advanced servo-technology and user friendly controls. We are very pleased to continue introducing more of these converting machines into the North America market throughout the next year.” Founded in 1995, Wasatch Container is one of Utah’s premier custom packaging design and manufacturers. The independent box maker specializes in corrugated shipping boxes, retail boxes, point of purchase displays, foam fabrication, and wooden crates. Wherever new opportunities arise, Wasatch Container works relentlessly to provide our customers with the most compelling packaging experience possible. Visit wasatchcontainer.com.

“We’ve had a relationship with Arvco for decades and the company is still a supplier to Opus,” says Manor. “One of their largest customers relocated up to Detroit, the lease on Arvco’s Indianapolis facility was coming due, and COVID-19 had hit them pretty hard, so it was time for them to make a decision as to whether or not they wanted to maintain a presence here in Indianapolis. We were in the process of finding equipment for our new Whitestown facility when the opportunity to acquire Arvco’s assets presented itself.” “It was a natural,” adds Stoner. “The assets from Arvco provided the much-needed equipment, as well as key employees and the sales infrastructure for our new startup, while renewing the friendship between the companies and ultimately, maximizing our efficiencies.”

Of the 30 employees now working at Opus Packaging – Whitestown, ten are from Arvco, which is seven miles from the Arvco Indianapolis facility. Several of Arvco’s temporary workers may also be joining the company. Opus brought in two of Arvco’s sales staff, including one full-time outside salesperson. The second is an inside salesperson, who doubles as a designer. Both brought “a good book of business” that will now be serviced by a company with a long history of providing stellar customer service.

|

|

|

German Engineering Meets Local Support: Kolbus America's Winning Combination

KOLBUS America blends the best qualities of superior quality German engineering and reliability, with the local service and support that you need to feel comfortable when purchasing a German machine.