Wasatch Container, is expanding their current facility while boosting their printing capabilities with the purchase of a new five color KOLBUS RD 115S Flexo Rotary Die Cutter with top print capabilities.

The purchase of this new machine comes as founder, Jerry Frisch, continues to grow the Salt Lake City based business with the expansion of his existing box plant. The 80,000 sq. ft. expansion extends to the neighboring building which will house the new RD 115S. Installation is planned for Q4 2022. Wasatch Container has also purchased a new conveyor system and complete scrap system to be installed in the new space with the KOLBUS RD115S.

“We’re very excited to upgrade our rotary die cut print capabilities and offer our customers new options from the KOLBUS RD115S,” said Jerry Frisch. “The ability to print on two sides in a single pass will boost throughput in the plant and increases Wasatch Container’s value to our customers.

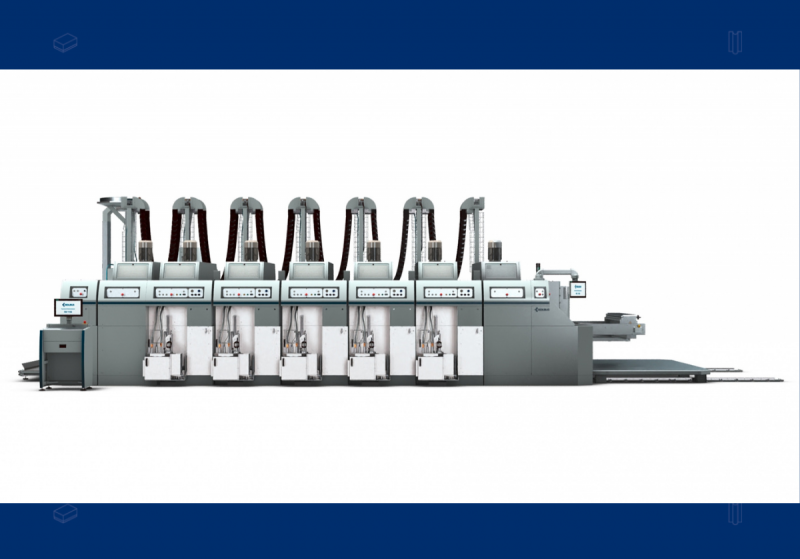

The German built RD 115S fully servo flexo rotary die cutter is the newest advancement from KOLBUS. This machine features advanced technology including image stretch/shrink functionality, plate skewing for fine adjustments without opening the machine, a feed unit with repeatable sheet separation with servo driven feed wheels and lift grid, and a rigid cast iron frame die cutter module. Wasatch Container will be the first in their region with this new KOLBUS RD 115S technology, and the second in North America to purchase this innovative machine.

“We look forward to partnering with Wasatch Container on increasing their print capabilities and continuing to grow their already successful corrugated business,” said Jeff Dietz, KOLBUS America President. “The RD 115S is a premium, German-engineered rotary die cutter with state-of-the-art automation, advanced servo-technology and user friendly controls. We are very pleased to continue introducing more of these converting machines into the North America market throughout the next year.”